Products

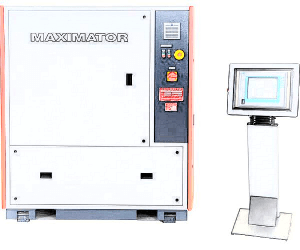

The MAXIMATOR RM350 Series Control Modules are precision Gas Controllers for Assisted Injection Molding up to 5000 psi.

The Control Modules are equipped with 2 or 4 gas control valves. Two interfaces allow the RM 500 Series Gas Control Modules to work with 1 or 2 injection molding machines at the same time.

Cores not moving as you need them to? Need a bit more pressure to get them to work properly?

You can spend time and money re-engineering larger cylinders into the mold, and devising ways to eliminate the problem. Or you can just give them more pressure with a ScanWill intensifer.

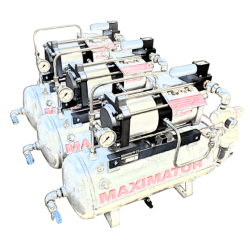

Maximator Compressor Stations are specially designed for the compression of nitrogen or carbon dioxide from gas bottles, and are employed for pressure generation in gas assisted molding applications.

The MAXIMATOR Gas Dosing Station is designed for the high-pressure dosing of gas for the physical foaming of plastics.

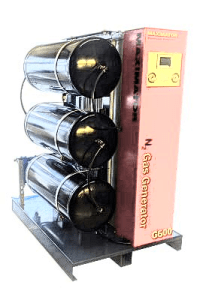

Nitrogen Generators use a workshop air supply to generate high purity nitrogen, which can then be utilised as it is at around 72psi or coupled with one of our compressor systems to generate an in-house high pressure nitrogen supply.

The MAXIMATOR Water Assisted System is suitable for assisted molding applications with water (WIT) in the area of assembly line production of component parts with large cross sections or channels. Considerably shorter cycle times and lower gas costs are a characteristic feature of this process variant.

These nozzles are suitable for a wide range of applications and can be applied to parts produced using the short shot, full shot and overspill gas assist processes.